Expertise

Research & development, Design

With the benefit of 40 years of experience in plastic injection and extrusion, MIP PLASTIC GROUP is guiding its customers from the design and co-conception of the plastic parts (Solidworks), the prototype sampling, the raw material choice, to the prototype or serial tools study and launch.

An integrated Research and development department is fully dedicated to review all your project requests.

MIP PLASTIC GROUP is CII CIR certified

MIP PLASTIC GROUP is CIR certified (Research Tax Credit) and is also CII certified (Innovation Tax Credit).

Working with MIP PLASTIC GROUP will allow you to get a tax credit of:

– 20% on your innovative projects

– 30% on your Research works

To know more about Reasearch Tax Credit HERE

MIP PLASTIC GROUP is guiding its customers to offer new tools according to specifications.

MIP is working with reliable and qualified suppliers which are strictly selected.

4000m2 of clean rooms splited in our 4 production plants (total 17.000m2 of buildings).

MIP PLASTIC GROUP is specialized in the plastic injection and extrusion since more than 40 years.

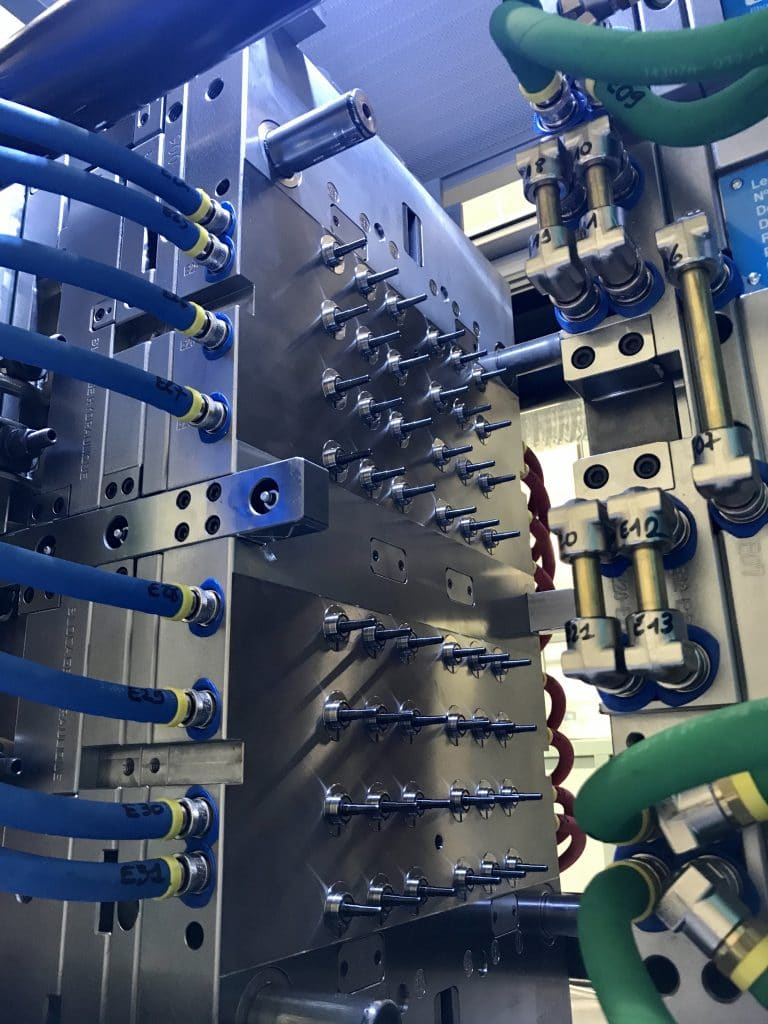

MIP PLASTIC GROUP has 10 extrusion lines and 55 injection molding machines from 40T to 400T.

MIP PLASTIC is offering completion services including in clean rooms:

- Overmoulding

- Automatic Assembly

- Pad-printing

- Welding

- Cap blister heat sealing

- Packaging

MIP PLASTIC GROUP has 2 metrology laboratories and offers several additional services which could be totally independant from our productions:

- 2D/3D controls

- Aspect controls

- Quotations

- Gauge design